Page 77 - Safety Express Catalogue 2017

P. 77

APP

APPAREL | PERSONAL PROTECTION AREL | PERSONAL PROTECTION

CHEMMAX COVERALLS

®

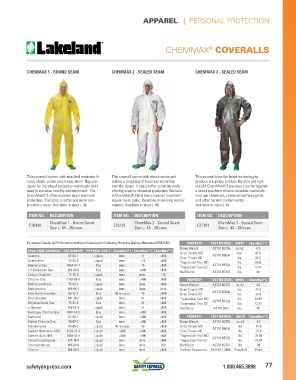

CHEMMAX 1 - BOUND SEAM CHEMMAX 2 - SEALED SEAM CHEMMAX 3 - SEALED SEAM

This coverall comes with attached respirator fit This coverall comes with elastic wrists and This coverall uses the latest technology to

hood, elastic wrists and ankles, storm flap over ankles, a respirator fit hood and storm flap produce a superior product. Durable and light-

zipper for increased protection and elastic back over the zipper. It has a softer substrate while weight, ChemMax® 3 provides a barrier against

used to increase mobility and movement. The offering superior chemical protection. Workers a broad spectrum of toxic industrial chemicals,

ChemMax® 1 offers superior liquid chemical in ChemMax® 2 find it much easier to perform dual use chemicals, chemical warfare agents

protection. The fabric is softer and more com- regular work tasks, therefore, increasing worker and other harmful contaminants.

fortable to wear. Available in sizes L-4X comfort. Available in sizes L-4X Available in sizes L-4X

ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION

ChemMax 1 - Bound Seam ChemMax 2 - Sealed Seam ChemMax 3 - Sealed Seam

C1B428 C72130 C3T151

Size L- 4X - 25/case Size L- 4X - 25/case Size L- 4X - 25/case

Permeation Data for ASTM Recommended List of Chemicals for Evaluating Protective Clothing Materials (ASTM F1001) PROPERTY TEST METHOD UNITS ChemMax 1

®

Basis Weight ASTM D3776 oz./y2 4.3

®

CHALLENGE CHEMICAL CAS NUMBER PHYSICAL STATE ChemMax 1 ChemMax 2 ChemMax 3 Grab Tensile MD lbs. 47.0

®

®

Acetone 67-64-1 Liquid imm. 9 >480 Grab Tensile XD ASTM D5034 lbs. 33.9

Acetonitrile 75-05-8 Liquid imm. <15 >480 Trapezoidal Tear MD lbs. 29.95

Ammonia Gas 7664-41-7 Gas imm. 15 >480 Trapezoidal Tear CD ASTM D5733 lbs. 12.47

1,3-Butadiene Gas 106-99-0 Gas imm. >480 >480 Ball Burst ASTM D3787 lbs. 48

Carbon Disulfide 75-15-0 Liquid imm. imm. 178

Chlorine Gas 7782-50-5 Gas imm. >480 >480 PROPERTY TEST METHOD UNITS ChemMax 2

®

Dichloromethane 75-09-2 Liquid imm. imm. >480 Basis Weight ASTM D3776 oz./sy 4.3

Diethylamine 109-89-7 Liquid imm. imm. imm. Grab Tensile MD lbs. 47.0

Dimethyl Formamide 68-12-2 Gas 40 minutes 18 >480 Grab Tensile XD ASTM D5034 lbs. 33.9

Ethyl Acetate 141-78-6 Liquid imm. 21 >480 Trapezoidal Tear MD lbs. 29.95

Ethylene Oxide Gas 75-21-8 Gas imm. 24 >480 Trapezoidal Tear CD ASTM D5733 lbs. 12.47

n-Hexane 110-54-3 Liquid imm. 21 >480 Ball Burst ASTM D751 lbs. 48

Hydrogen Chloride Gas 7647-01-0 Gas imm. >410 >480

Methanol 67-56-1 Liquid imm. >480 >480 PROPERTY TEST METHOD UNITS ChemMax 3

®

Methyl Chloride Gas 74-87-3 Gas imm. >480 >480 Basis Weight ASTM D3776 oz./y2 4.3

Nitrobenzene 98-95-3 Liquid 45 minutes 45 >480 Grab Tensile MD lbs. 47.0

Sodium Hydroxide, 50% 1310-73-2 Liquid >480 >480 >480 Grab Tensile XD ASTM D5034 lbs. 33.9

Sulfuric Acid, 98% 7664-93-9 Liquid >480 >480 >480 Trapezoidal Tear MD lbs. 29.95

Tetrachloroethylene 127-18-4 Liquid imm. imm. >480 Trapezoidal Tear CD ASTM D5733 lbs. 12.47

Tetrahydrofuran 109-99-9 Liquid imm. imm. 320 Ball Burst ASTM D3787 lbs. 48

Toluene 108-88-3 Liquid imm. imm. >480 Surface Resistance EN1149-1:2006 Pass/Fail Pass

safetyexpress.com 1.800.465.3898 77