Page 66 - Safety Express Catalogue 2017

P. 66

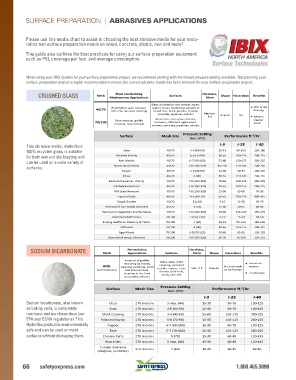

SURFACE PREPARATION | ABRASIVES APPLICATIONS

Please use this media chart to assist in choosing the best abrasive media for your resto-

ration and surface preparation needs on wood, concrete, plastic, iron and more!

Approved Green Abrasives

This guide also outlines the best practices for using our surface preparation equipment:

such as PSI, coverage per foot and average consumption.

Media Guide

When using your IBIX System for your surface preparation project, we recommend starting with the lowest pressure setting available. Test patching your

surface preparation project is highly recommended to ensure the correct abrasive media has been selected for your surface preparation project.

CRUSHED GLASS

CRUSHED GLASS

This abrasive media, made from 100% recycled glass, is suitable for both wet and

dry blasting and can be used on a wide variety of surfaces.

This abrasive media, made from

Plant and Building

100% recycled glass, is suitable Surfaces Hardness, Shape Hazardous Benefits

Mesh

Maintenance Applications

for both wet and dry blasting and Mohs

can be used on a wide variety of

surfaces. Slate, polished or raw marble, stone,

Restoration, gum removal,

40/70 mill scale removal, cleaning copper, brass, hardwood, painted or Wet & dry

blasting

rusted iron, brick, granite, chrome,

concrete, pipelines, railcars Medium, Angular No

5-6 Whiter,

Aluminum, satin glass, plastics, cleaner

Paint removal, graffiti

70/100 removal, rust removal masonry, softwood, aged wood, finish

chrome, concrete, pipelines, railcars

Approved Green Abrasives

Media Guide

Pressure Setting

Surface Mesh Size Performance ft.²/hr.

Bars (PSI)

I-9 I-25 I-40 HiPro 60

Slate 40/70 4-6 (60-90) 20-45 80-105 160-186 320-345

SODIUM BICARBONATE

SODIUM BICARBONATE 40/70 5-6 (70-90) 30-55 100-125 200-225 400-425

Polished Marble

Raw Marble 40/70 6-7 (90-100) 55-80 150-175 300-325 600-625

Stone, Hard Stones 40/70 7-8 (100-120) 85-105 120-145 240-265 480-500

Sodium bicarbonate, also known as baking soda, is completely non-toxic and non-hazardous

Copper 40/70 2-6 (30-90) 15-30 50-75 100-125 200-225

(per EPA and OSHA regulations). It is also approved by the USDA as an A-1 Cleaner for use in

Brass food processing or FDA regulated facilities. This Hydroflex product is environmentally safe 240-265 480-500

6 (90)

30-55

120-145

40/70

and can be used on most surfaces without damaging them.

Hardwood (walnut, cherry) 40/70 7-8 (100-120) 40-65 150-175 300-325 600-625

Painted/Rusted Iron 40/70 7-8 (100-120) 20-55 100-125 200-225 400-425

Sodium bicarbonate, also known Hardness,

Remediation

15-30

40/70

Mill Scale Removal

7-8 (100-120)

as baking soda, is completely Applications Surfaces Mohs Shape Hazardous 35-60 70-95 140-165

Benefits

Mesh

non-toxic and non-hazardous (per 40/70 4-5 (60-70) 50-75 200-225 400-425 800-825

Exposed Brick

EPA and OSHA regulations). This

Rough Granite

40/70

Removal of graffiti,

Hydroflex product is environmentally Glass, slate, mold 8 (120) 5-10 15-30 30-45 60-80

removing barnacles,

30-55

safe and can be used on most cleaning, polis 5 (70) No, but needs Leaves no 60-85 120-145

Removal of non weeds (chrome)

15-30

40/70 hed

ASXL

residue

cleaning, polishing, mold

surfaces without damaging them. marble, copper, teak, Soft, 2-3 Angular to be flushed 125-150 250-275 300-325

(270 microns)

Removal of Vegetation and Barnacles

7-8 (100-120)

40-65

40/70

and soot removal,

cleaning in the food chrome, boat hulls, Eco-friendly

70/100

Aluminum/Satin Glass pools, cars, tile 2 max. (30) 5-10 15-30 30-50 60-85

processing industry

Erasing Graffiti on Masonry & Plastic 70/100 4 (60) 30-45 90-115 180-205 360-385

Softwood Pressure Setting 4 (60) 40-65 150-175 300-325 600-625

70/100

Surface

Mesh Size

66 safetyexpress.com Bars (PSI) Performance ft.²/hr. 1.800.465.3898

Aged Wood 70/100 6-8 (90-120) 40-65 65-85 130-155 260-285

HiPro 60

I-40

7-8 (100-120)

Removal of weeds (chrome) 70/100 I-9 I-25 20-30 75-100 150-175 300-325

Glass 270 microns 3 max. (44) 15-30 50-75 100-125 200-225

When using your IBIX System for your surface preparation project, we recommend starting with the lowest pressure setting available.

270 microns

4-6 (60-90)

50-75

Slate

100-125

200-225

20-45

Test patching your surface preparation project is highly recommended to ensure the correct abrasive media has been selected for your surface preparation project.

Mold Cleaning 270 microns 3-4 (45-60) 55-80 150-175 300-325 600-625

Polished Marble 270 microns 5-6 (70-90) 30-55 100-125 200-225 400-425

Copper 270 microns 4-7 (60-100) 15-30 50-75 100-125 200-225

Teak 270 microns 5-7 (70-100) 20-45 100-125 200-225 400-425

Chrome Parts 270 microns 5 (70) 15-30 60-85 120-145 240-265

Boat Hulls 270 microns 3 max. (45) 15-30 60-85 120-145 240-265

Tubular Elements

(dinghies, pontoons) 270 microns 4 (60) 10-20 30-45 60-85 120-145

When using your IBIX System for your surface preparation project, we recommend starting with the lowest pressure setting available.

Test patching your surface preparation project is highly recommended to ensure the correct abrasive media has been selected for your surface preparation project.